Hard Metal: Cryogenics in Alberta and the Impact on our Oilsands

In the last blog we separated some myths from facts about cryogenics. Now that you know cryogenics can be applied to almost every industry, let’s take a closer look at cryogenics in Alberta.

There is no doubt about it. Alberta is run on industry. While the technology sector is quickly turning into a powerful economic contender, when you hear Alberta, you think oil and gas.

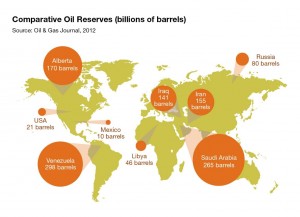

Alberta’s oilsands accounted for over 22 per cent of the province’s gross domestic product in 2012 and as of last year, there were well over 100 active oilsands products in Alberta. Alberta’s oil production is very strong in the world market as evidenced by the infogram below.

When we have a resource that is so important to our wellbeing as a province and a country, it makes good sense to find ways to access this resource in the most efficient manner. That is where cryogenics in Alberta comes into play.

There are many ways cryogenics in Alberta is used; and one of these ways is to increase the durability of oilsands tools. Just think of all the equipment used in the oil sands: the heavy hauler trucks that transport the product, fleet vehicles going to and from sites, all those small parts and gears inside the machinery and even the hand-held tools needed on the job site. When we take these metal components and treat them cryogenically, we dramatically increase their durability.

Wikipedia provides an excellent explanation:

[Treating metals cryogenically] can have a profound effect on the mechanical properties of certain steels, provided their composition and prior heat treatment are such that they retain some austenite at room temperature. It is designed to increase the amount of martensite in the steel’s crystal structure, increasing its strength. Presently this treatment is being practiced over tool steels, high-carbon, and high-chromium steels to obtain excellent wear resistance. Recent research shows that there is precipitation of fine carbides (eta carbides) in the matrix during this treatment which imparts very high wear resistance to the steels.

In short, cryogenics makes metal tools/components stronger and makes them last longer.

Cryogenics in Alberta improves the way we mine our valuable resources. Any time equipment breaks down or needs to be repaired, there is a loss of time and dollars. As disagreeable as the saying “time is money” can be, it is true. The time spend repairing or replacing equipment cuts sharply into profits.

Additionally, major oil sands developers are always interesting in using eco-friendly processes. They know mining has an unsavory reputation when it comes to land conservation and protection; therefore they work tirelessly from the outset of each project to make sure the land is protected, reclaimed and as little waste is produced as possible. When these developers invest in cryogenics in Alberta, they reduce the amount of waste they produce because their tools and tool parts last longer and work better.

Cryogenics in Alberta makes our important work in the oilsands more efficient and less wasteful; and since the oilsands help to power our prospering province, any clean, environmentally friendly, cost-effective process that improves energy mining is a process worth investing in.

Millennium Cryogenics Technologies is pleased to provide cryogenics in Alberta to improve the wear resistance of metal tools. Contact us today to learn more about how we can help you.